Main content

Design Services

Custom & Prototype

Custom Design and Engineering

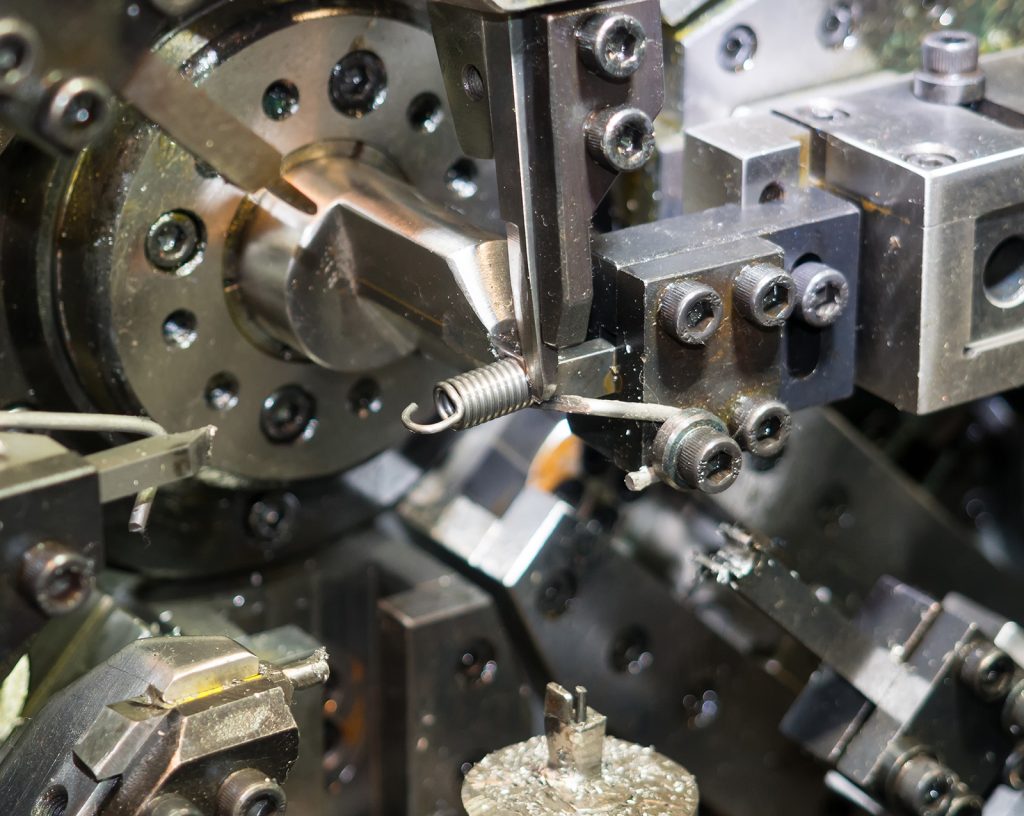

To ensure custom springs are produced to your exact specifications, our design and prototype service includes six steps:

- Gather client requirements or provide reverse engineering services based on sample

- Fabricate prototype or other custom item

- Refine prototype and suggest best options for production and parts until client approval received

- Document manufacturing procedure, including parts required, assembly procedure, and keep on file

- Begin productions

- Deliver product

Contact us to begin work on your custom spring design.

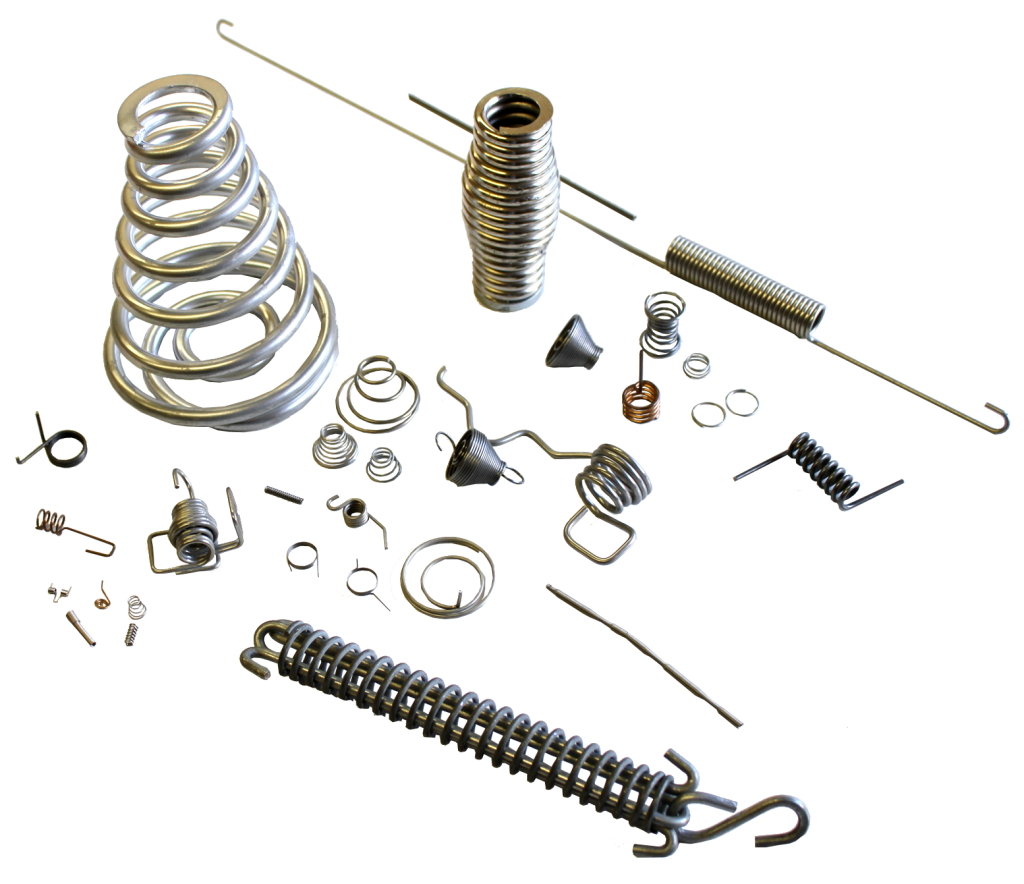

Spring Manufacturing Materials

- Music wire

- Oil tempered MB Wire

- Hard Drawn MB Wire

- Chrome Cadmium Wire

- Chrome Silicon

- Hot-rolled carbon spring steel

- Hot-rolled chromium spring steel

- Stainless steel wire

- Phosphor bronze spring wire

- Spring brass wire

Once a product has a smooth finish, we can apply additional finishing methods for extra strength, durability, and safety, including:

- Shot Peening – a cold-working process in which the material surface is peened with steel shot to induce compressive stresses and thereby improve fatigue life

- Heat Treating & Stress Relieving – metal hardening processes

- Chemical Cleaning – a method for removing manufacturing product residues

- Plating – anti-corrosion protective layer

- Powder Coating – an anti-contamination protective layer

- Galvanizing – the process of applying a protective zinc coating to prevent rusting

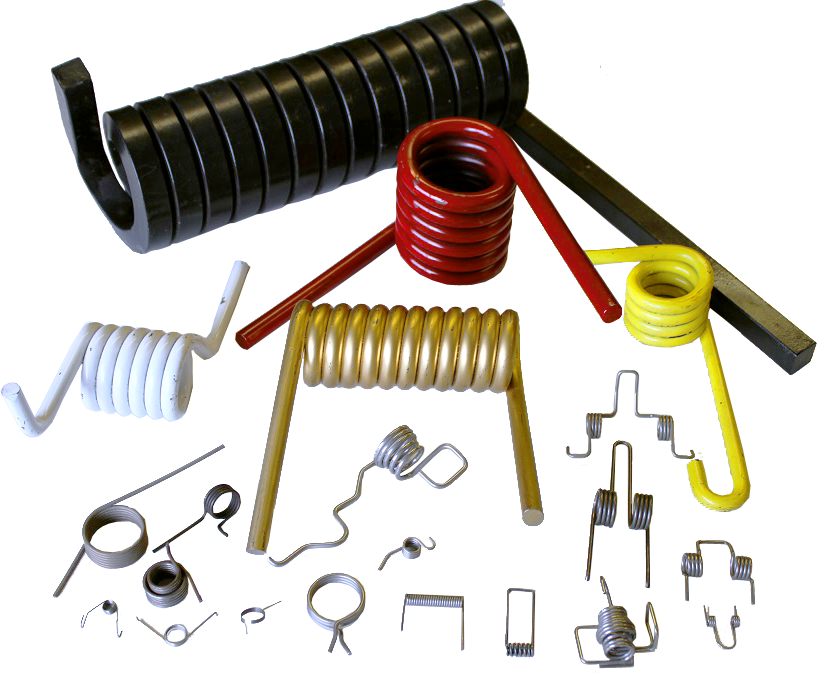

Spring Protective Coatings

- Cadmium plate

- Zinc plate

- Rustproof dip or spray

- Phosphate

Let us help you get started on your project.